Step 6

Processing: Roasting and Grinding

The processing stage typically encompasses roasting and grinding of cocoa beans. In the past, these operations were performed almost entirely in importing countries, but nowadays, origin countries are also increasingly engaged in processing.

Cocoa is roasted to reduce water content and to obtain rich aromas and flavor from the beans. This can be done on the whole beans before shelling (i.e. bean roasting), or on the nib after shelling (i.e. nib roasting). Sometimes, the removed shell that covers the nibs is sold and used as agricultural mulch or by fertilizer producers. After the beans are roasted, they undergo other processes, including alkalization, which makes semi-finished cocoa products darker and reduces their acidity. The time and temperature for roasting the beans are key determinants of the flavor of the semi-finished products.

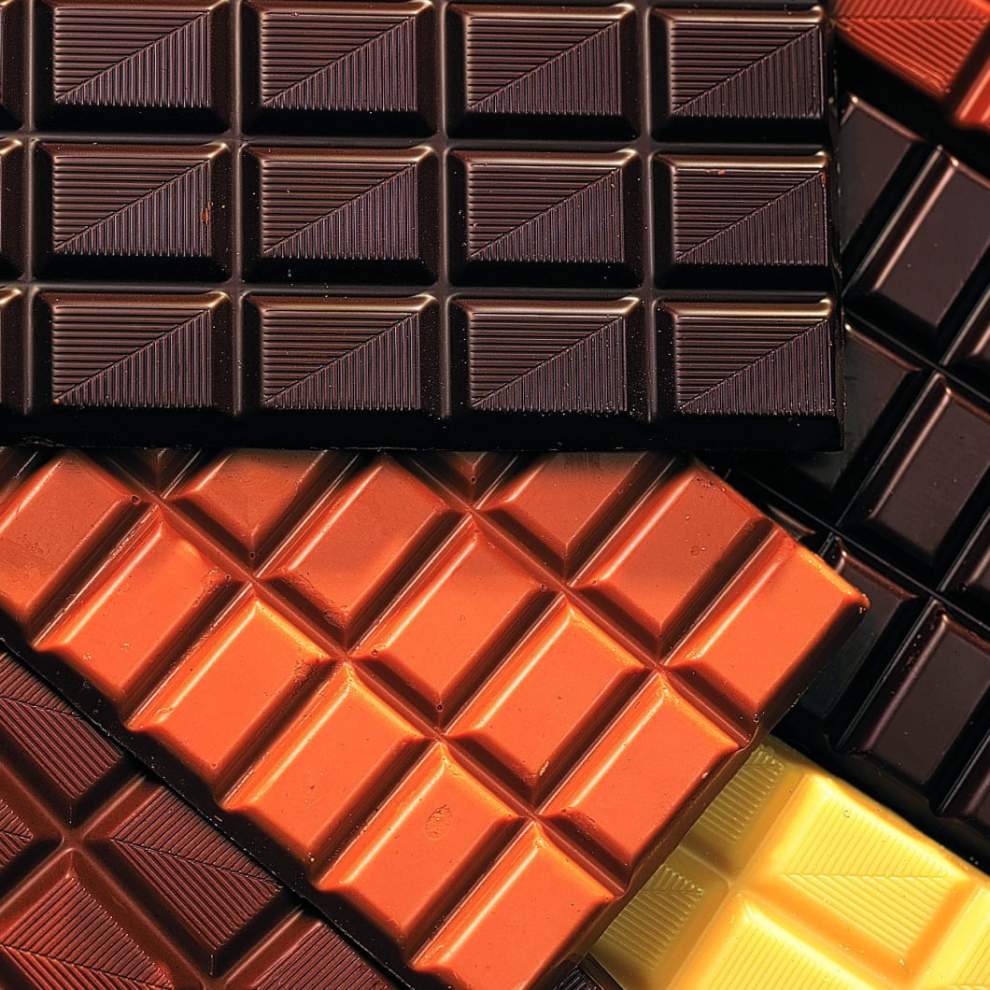

After the beans have been shelled and roasted, the nibs are ground to produce fine cocoa liquor under high temperatures. The cocoa liquor may be used directly as an ingredient for chocolate. Otherwise, it is pressed through a fine sieve, leaving a solid material called cocoa cake. The extracted cocoa butter is then filtered and stored in tanks in liquid form for use in chocolate manufacturing. The cake is either broken into smaller pieces and sold in generic cocoa markets or pulverized to produce a fine cocoa powder. Cocoa cake generally varies in terms of the fat content, depending how much fat has been pressed out. This determines the end use, ranging from drinking chocolate to bakery products.